Closely following the national strategic deployment of comprehensively strengthening ecological and environmental protection and resolutely fighting the battle against pollution, and strictly abiding by the relevant national regulations and requirements for the discharge of pollutants, the Company has taken multiple measures to deal with waste water, liquid and waste generated in the production process, reducing total pollutant discharges, improving the pollutant recycling capacity and level, and achieving remarkable comprehensive benefits. In 2018, the Company won the honor of “National Green Manufacturing Integration Project” from the Ministry of Industry and Information Technology.

(1) Wastewater and Waste Liquid Management

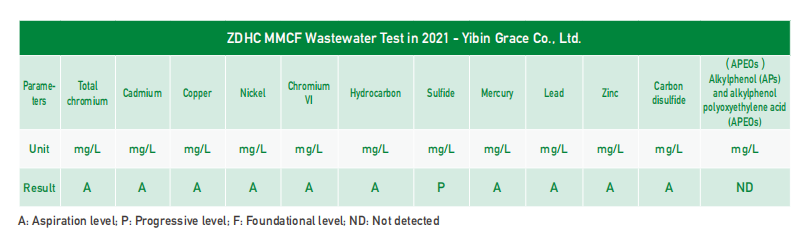

During producing cellulose fibers, a large number of pollutants such as waste alkali liquor,waste glue, acid bath water and plasticized water will be produced. The main pollutants contained in the wastewater and waste liquid discharged by the Company include chemical oxygen demand, ammonia nitrogen (NH3-N), total nitrogen (N), total phosphorus (P), suspended solids, fiveday biochemical oxygen demand, sulfide, total zinc, etc. To this end, the Company implements environmental objectives centering on strengthening source control, environmental monitoring and technical monitoring, carries out the pre-control of environmental pollution, pays close attention to sewage treatment, ensures up-to-standard discharge and prevents environmental risks.

In addition, the company has taken measures such as upgrading sewage facilities and biochemical treatment facilities, optimizing treatment technology and making technological innovation to improve its sewage treatment capacity and sewage recycling level, so as to promote source treatment and resource recycling to the largest extent; it optimized existing sewage treatment process by screening and domesticating special strains resistant to high acid and high salt environment and Improve the biochemical treatment capacity of wastewater; it can efficiently recycle the treated wastewater to the production system by innovating the advanced oxidation and negative pressure degassing filtration technology, improving the wastewater recycling rate.

(2) Waste Management

The Company’s solid waste mainly includes general solid waste and hazardous waste. The former includes waste silk, paper and cardboard, plastic, metal and household waste, while the latter includes waste mineral oil and waste packaging containers. In strict accordance with the Law of the People's Republic of China on the Prevention and Control of Environment Pollution Caused by Solid Wastes and other relevant regulations, the Company strengthens the standardized management of solid waste and hazardous waste in combination with the actual situation to carry out reduction, recycling, and harmless disposal of solid waste, so as to reduce the risk of environmental pollution.

At present, the Company has established a perfect solid and hazardous waste management regulation; it has also established storage warehouses for hazardous waste, implemented standardized management of hazardous waste, and entrusted qualified third parties for disposal according to relevant regulations. The Company will carry out regular verification of the main qualification and technical capacity of the entrusted parties and strictly implement the regulations related to hazardous waste transfer, so as to realize the traceability of hazardous waste.